Kaira SPM & Automation, Design and Develop high speed, precise & Robust Automatic Linear & Rotary Assembly lines as per customer processes & requirement.

Key Features:

- The equipment adopts the automatic loading and unloading mode

- The fixture is finely designed, durable and easy for maintenance

- Multi-station Assembly, Gluing, Marking & EOL Testing

- Complete traceability & Reporting

- Low maintenance, Diagnostics enabled system

- Latest Technology Edge scalable solution

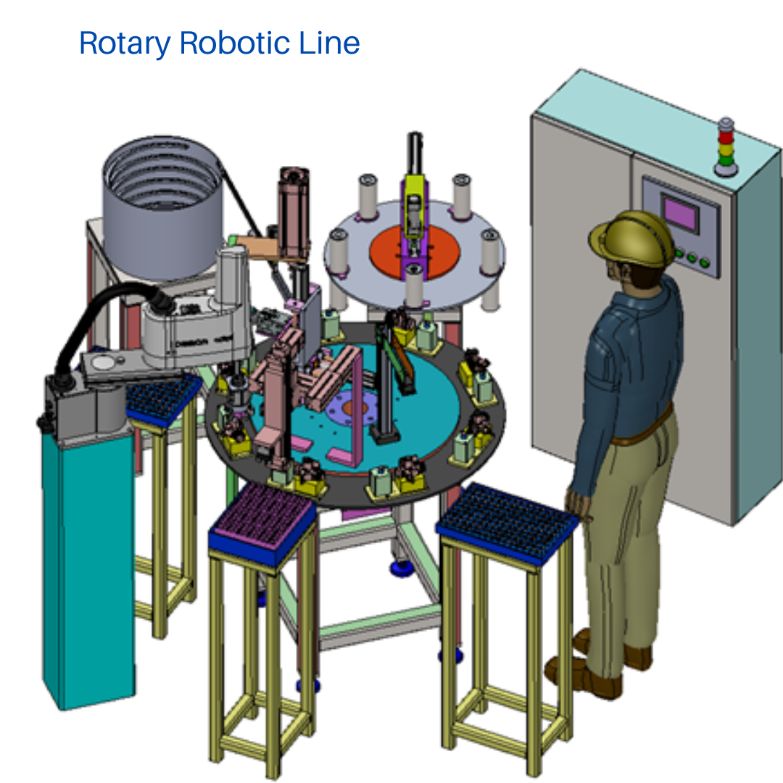

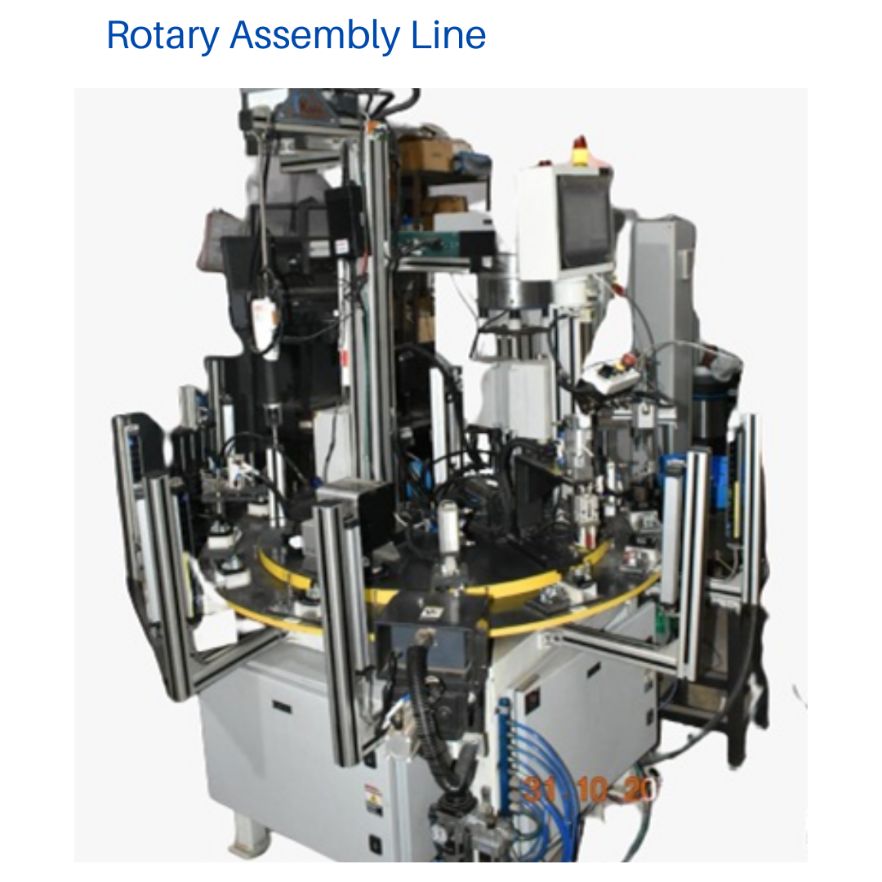

Rotary Assembly Line

Kaira Design & Develop Automatic & Semi-Automatic Rotary line for the assembly and testing of the product for fast and accurate production.

Kaira developed rotary line for varied products Categories and varied industries including Automobile automation industries & Specific as per Customer Requirement.

Features:

- Multi Station for assembly and testing.

- Part transfer with high accuracy less than 15 micron thru Electronic Indexing mechanism.

- Child parts feeding by using vibratory feeders, pick and place by the Gantry or Robot.

- We integrate automatic part feeding, loading and unloading, riveting, screwing, testing in these machines.

- Integrated vision system for Poke Yoke, all communication on Ethernet/IP.

- Fully informative HMI & operator friendly system design.

- Complete Traceability of parts and processes.

- We manufacture up to 1800mm diameter rotary indexer for assembly line.

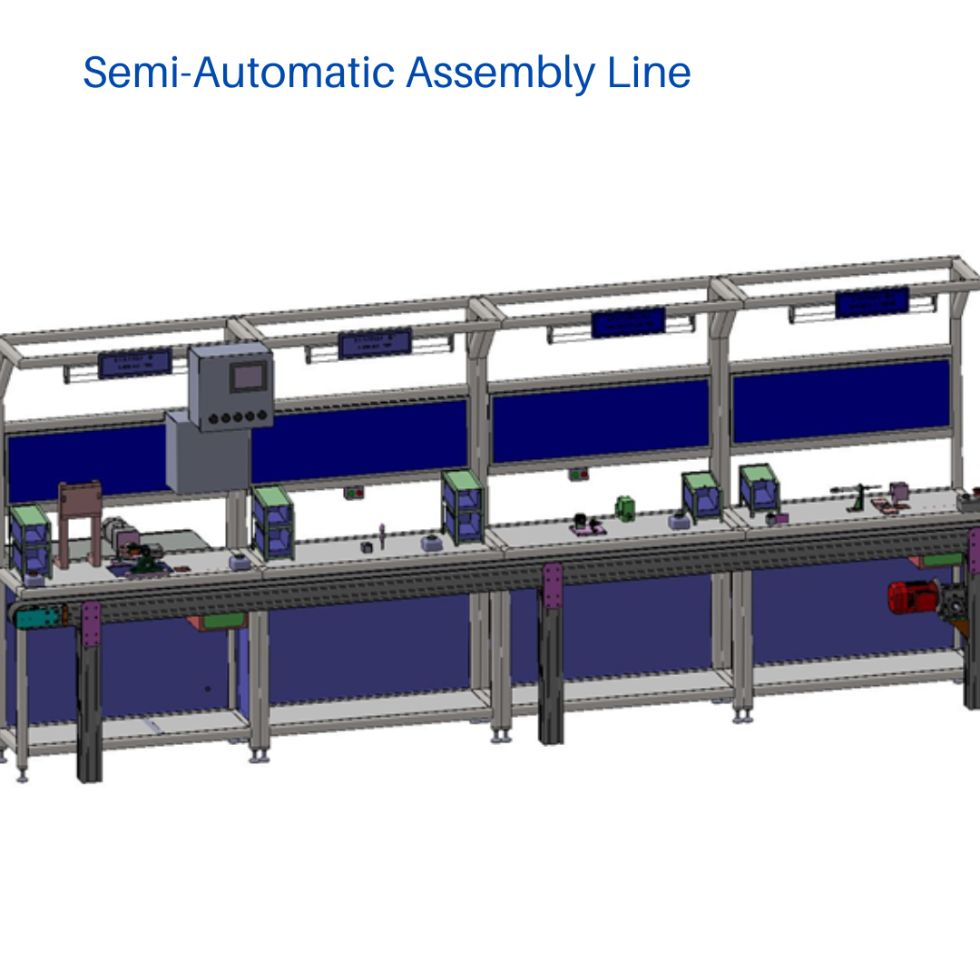

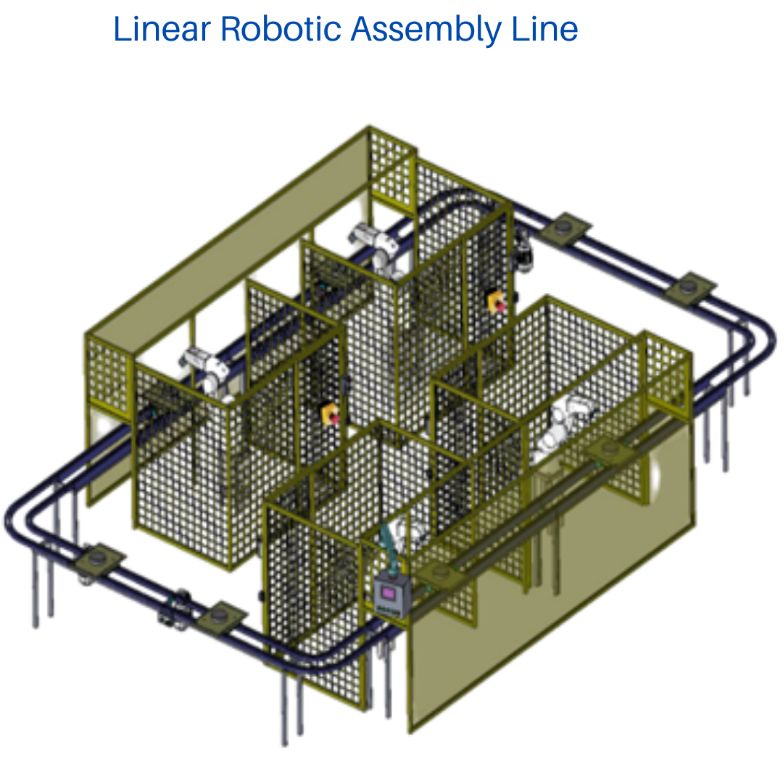

Linear Assembly Line

Kaira Design & Develop Automatic & Semi-Automatic linear transfer line for the assembly and testing of the product for fast and accurate production with the integration of Pallet conveyor & belt conveyor for Part transfer.

Kaira Design & Development contains linear transportation system line with human safety, and enabling fast, stable and accurate production flow, for varied products Categories and varied industries including Automobile automation industries & Specific as per customer’s process & requirement.

Features:

- Multi Station working for assembly & testing of product.

- Line Balancing as per cycle time & operation.

- Auto marking as per running model at station, marking communication with PLC for model tracking on network.

- We integrate automatic part feeding, loading and unloading, riveting, screwing, welding, testing in these machines.

- Integrated vision system for Poke Yoke, all communication on network.

- Fully informative HMI & operator friendly system design.

- Complete Traceability of parts and processes.