Kaira Design & Develop Semi-Automatic / Automatic washing machine with conveyor linear transfer line for fast and accurate production.

Kaira develop washing machine as per customer requirement and in products Categories. It Includes bin or crate washing, Component washing, Ultrasonic washing & Greasing washing.

Kaira develop washing machine as per customer requirement and in products Categories. It Includes bin or crate washing, Component washing, Ultrasonic washing & Greasing washing.

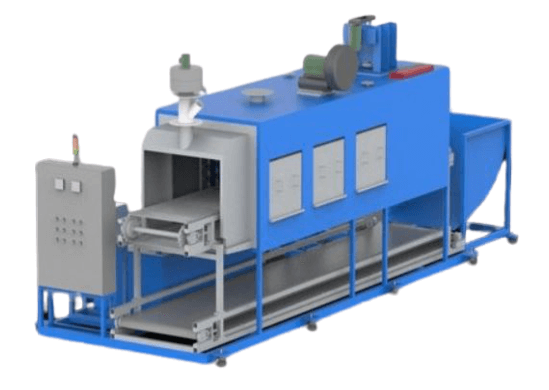

Bin or Crate Washing Machine

Bin or crate cleaning machine enables customers to handle the whole crates washing process efficiently and with a high continuous output as much as more crates per hour. Grease, Oil, Loose burrs and other contaminants are left on components after machining and other Processes. For the cleaning to avoid contamination carried to the component our crate washer machine is perfect solution for this type of crate washer application.

Specification:

- Washing machine will wash, rinse and dry within supervision by one person.

- Stainless steel link conveyor moves to wash chamber for chemical washing media water based after that enters into hot water rinse chamber & after that drying chamber for cleaning.

- High Pressure spray jet nozzles for washing.

- Hot air blower used for drying bin or crates.

- Its saves water, labour, time, chemicals and scratching.

- We manufacture up to 1000x1000x500 mm crate size & can be manufactured as customer requirement or customize length and width crate and bin 600x400x200 mm bin size washing machine.

Part Washing

Part cleaning machine enables customers to handle the high-volume componentcleaning process efficiently and with a high continuous output as much as more components per hour. Grease, Oil, Loose burrs and other contaminants are left on components after machining and other processes. For the cleaning to avoid contamination carried to the component our component washer machine is perfect solution for this type of component washer application.

Specification:

- Washing machine will wash, rinse and dry within supervision by one person.

- Stainless steel link conveyor moves to wash chamber, rinse chamber & drying chamber for cleaning.

- High Pressure spray jet nozzles for washing.

- Hot air blower used for drying components.

- Its saves water, labour, time, chemicals and scratching.

- We manufacture up to 1000 mm width for component washing machine.

Ultrasonic Washing Machine

The Ultrasonic is the science of sound waves. These sound waves form a bombarding effect on material to be cleaned. To extract the effectiveness of ultrasound it requires a medium such as water or solvent for the waves to propagate.

The object to be cleaned is immersed in the solvent and the ultrasound is passed to the solvent. As the waves pass, the liquid fractures or tears because of the negative pressure. This pressure builds up and finally the violent collapse of the cavitation bubbles result in implosions which causes shock waves to radiate.

Ultrasonic Cleaners are widely used to clean intricate parts. The ultrasound generator generates High Frequency, which is applied to water. Thus, water starts resonating at that frequency. This pulsating water molecules splash on the submerged jobs, which in turn get impounded by this frequency. This action loosens the dirt from cavities.

Specification:

- Washing machine will wash, rinse thru ultrasonic waves blast and dry within supervision by one person.

- Stainless steel Basket Bin moves thru gantry to wash chamber for chemical washing media water based after that enters into hot water rinse chamber with the help of ultrasonic waves generation & after that drying chamber for cleaning.

- Hot air blower used for drying components.

- We manufacture up to 800 x 800 x 5000 mm Basket Bin Size for component washing machine.